Hippocratic Implant

Hips Don‘t Lie

(iBiomed Project 2)

The patient Jackie Chiles, a 65-year-old man, has experienced debilitating hip pain since the age of 10 as a result of suffering from Legg-Calves Perthes Disease. This discomfort has become more intense overtime, impeding his ability to walk and previous treatments are no longer effective resulting in the need of a specialized total hip replacement.

Evidence-based Solution

The Hippocratic Implant is our evidence based solution which uses various personalized technologies that fit the needs and profile of our patient.

The project is:

- Built and designed with appropriate material research

- Fully functional and to scale

- Considers personal profile of a specialized client.

Completed Learning Objectives

- Effectively using the Engineering design process

- Created and designed a poster board that displayed our hip implant

- Used 3D design software to print a physical model of hip implant.

- Utilized Python to program code that can verify design parameters to patients profile.

- Using Material Data to analyze feasability

- Demonstrating effective teamwork on a group based design project.

Applied Skills

Technical Skills

Autodesk Inventor

Autodesk Inventor PrusaSlicer (3D Printing)

PrusaSlicer (3D Printing) Python

Python PowerPoint

PowerPoint

Soft Skills

- Presentation skills

- Project management

- Teamwork

Milestone 1 🔗

- As a group created diagnosis for our patient’s condition.

- Defined a need statement specific to our case file

- Compiled a list of objectives and constraints for our design solution.

Milestone 2 (Ind🔗 and Team🔗)

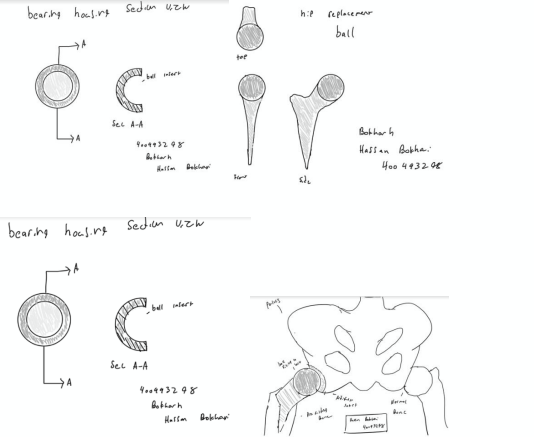

- Individually generated a preliminary concept solution sketches.

- Based on group members preliminary concepts we refined to a final concept sketch

Personal Contributions

- Responsible for development and assembly of posterboard

- Conducted research on appropriate materials

- Developed a computer program with python that can verify design parameters to patients profile. (Coding Sub-team)

- Aided CAD sub-team by creating assembly of parts and engineering drawings🔗for all parts.

- Responsible towards keeping track of all resources as subject matter expert.

- Used previous experience with 3D printing to take leadership responsibility towards printing a working 3D model.

- Conducted an Independent research in Healthcare (IRH 🔗)

Final Deliverables

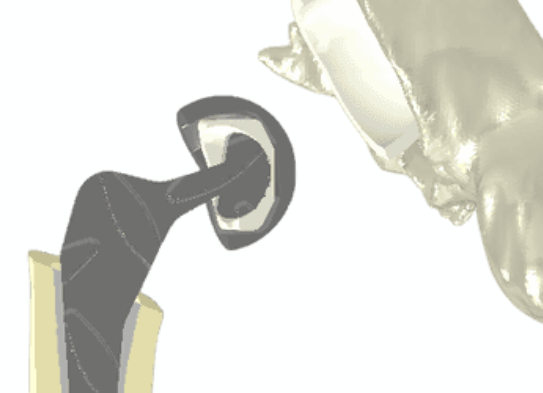

Poster Board 🔗

We created a poster board that clearly describes our final design for our hip implant. This was achieved through images of our 3D model. The shape and material of our hip implant were justified and clearly explained along with its fixation to the bone. This posterboard was used as a display for our DP-2 project showcase where we presented our idea to judges.

Computer Program 🔗

Our final computer program testing the various design parameters to patients profile. The code consists of three subprograms that approximately calculate:

- Smallest diameter of the implant at certain conditions

- The fatigue life for our implant design.

- Number of years post-implantation before risk of femoral fracture

Final Prototype 🔗

Our final prototype was created with a 3D printer. It was modelled based on our patients bone structure and unique condition. This was done through the use of Autodesk Inventor as well as PrusaSlicer.

Design Report 🔗

Our design report included a summary of our individual contributions as well the 3D printing process for our hip implant

Personal Reflective Summary

“None of us is as smart as all of us” -Ken Blanchard

As I reflect on my experiences in Design Project 2, this quote by Ken Blanchard really stands out to me. Working with a team on this project, I learned firsthand the importance of collaboration and seeking diverse perspectives in problem-solving. One thing I really appreciate about our team was the way we were able to bounce ideas off of each other and come up with a design that was not only functional, but also took into consideration the needs and preferences of our patient, Jackie Chiles. I remember feeling a bit overwhelmed at the start of the project, wondering how we were going to be able to come up with a successful prototype given the complexities of the patient’s condition. But as we worked together and brainstormed different approaches, I saw how much we were able to accomplish as a team.

I also learned the value of seeking help and expertise from others. As a subject matter expert and coding team sub member on this project, I was responsible for keeping track of resources as well as designing a computer program for analyzing selected design parameters. However, I also knew that I couldn’t do it all on my own. I had to rely on the expertise of my teammates, particularly those on the coding and solid modeling teams, to help bring our design to life. And I’m so grateful for their contributions, because without them, I don’t think we would have been able to create such a comprehensive and innovative prototype. Overall, this project was a great reminder that we can achieve so much more when we work together and leverage the diverse skills and knowledge of our team. As we move forward in our careers, I hope to continue to embrace this concept of “None of us is as smart as all of us” and seek out opportunities to collaborate and learn from others.