DP – 4

Not a Pun, It’s Real Life

(iBiomed Project 4)

👤 Background

David is a quadriplegic individual who is paralyzed from the chest down and has limited hand mobility. Despite his physical limitations, he is passionate about sports and has set a goal to complete an IRONMAN triathlon. David wishes to overcome physical challenges to participate in swimming activities, including competitive events. He is determined to maintain his independence in the water and pursue his passion for swimming while breaking down barriers.

Identified Solution

❤️ Need

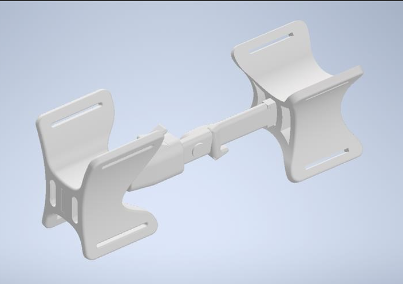

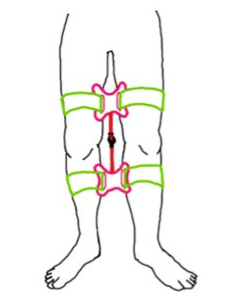

The GlideMaster is a swimming brace designed for individuals with limited mobility, such as quadriplegics.

- It aims to enhance swimming performance by reducing hydrodynamic drag and making the user more streamlined in the water.

- The brace features a knee-locking mechanism, Velcro straps for secure attachment, and thumb hooks for ease of use.

- Constructed from PLA+, the neutrally buoyant GlideMaster is both durable and compliant with Ironman guidelines.

Design a solution for David that helps improve his swimming by reducing drag and making him more streamlined in water. The solution must be waterproof, must not depend on the movement of the legs or hips, and must not make him dependent on someone else.

🎯Objectives

- Should improve swimming

- Should adhere by Ironman guidelines

- Must make him more streamlined in water

- Should be comfortable

- Should be affordable for the client

🚧 Constraints

- Must be waterproof

- Must not impede swimming progress

- Must not depend on movement of legs and hips

- Must not make him dependent on someone else

🔑 Functions

- Helps reduce drag

10$ to make

Possibility of further reducing costs through mass production and alternative manufacturing methods

🧑 My Individual Contributions

- As project coordinator, created a log of all additional meetings as well as creating detailed notes and a summary on the topics discussed.

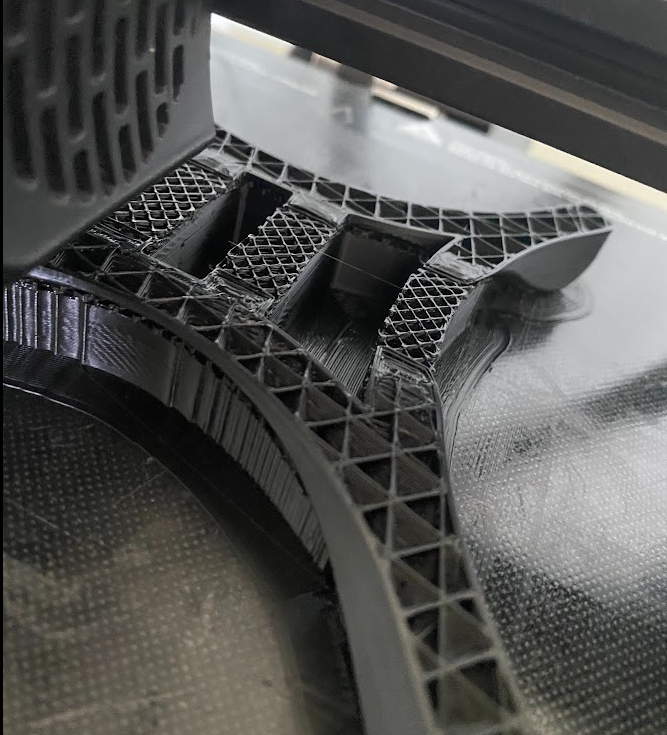

- Utilized CAD towards creation and design of all components of the 1st, 2nd, 3rd and final 3D printed prototype on my personal 3D printer.

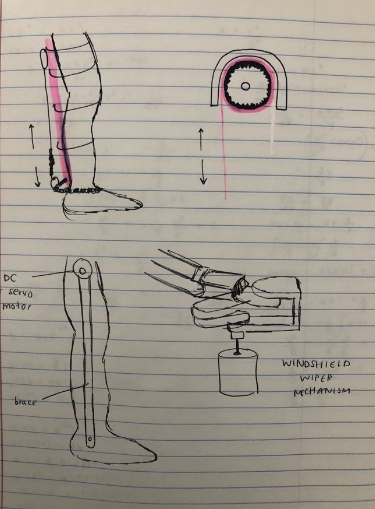

- Developed an automatic locking mechanism from scratch as-well as thumb hooks to account for dexterity restrictions with the customer base.

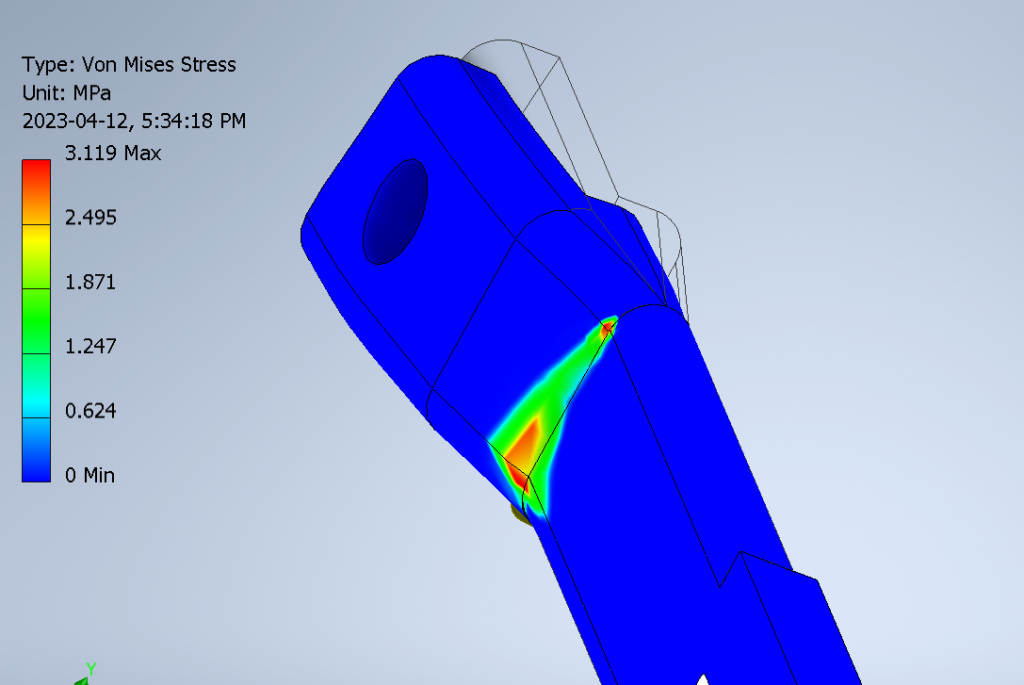

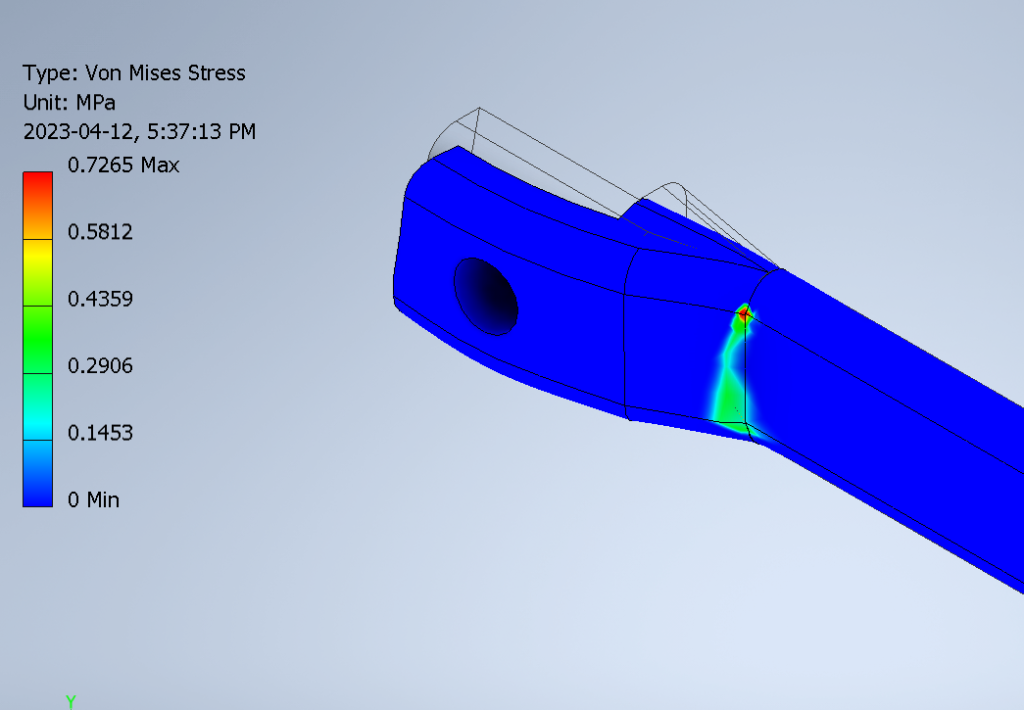

- Conducted extensive material research and testing using both inventor software and in person testing to come up with a viable material to print with.

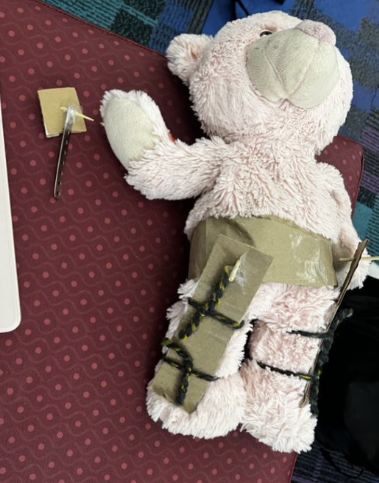

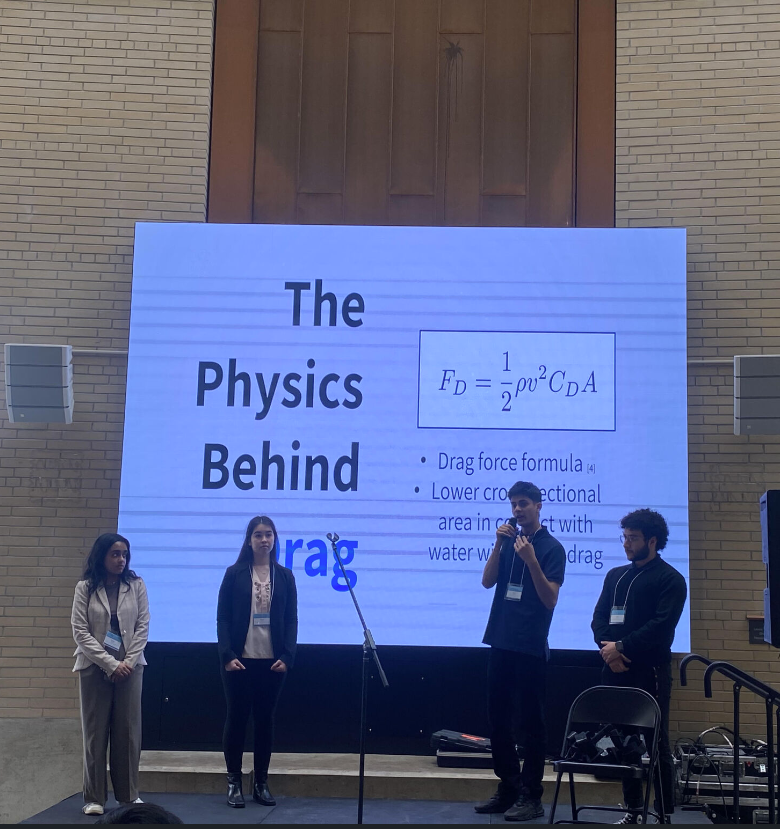

Contribution Images

🔨 Applied Skills

🧠 Soft Skills

- Idea Generation

- Time management

- Note – taking

- Presentation

⚙️ Hard Skills

Autodesk Inventor

Autodesk Inventor PowerPoint

PowerPoint PrusaSlicer (3D Printing)

PrusaSlicer (3D Printing)- 🛠️ Prototyping

📐 Design Process

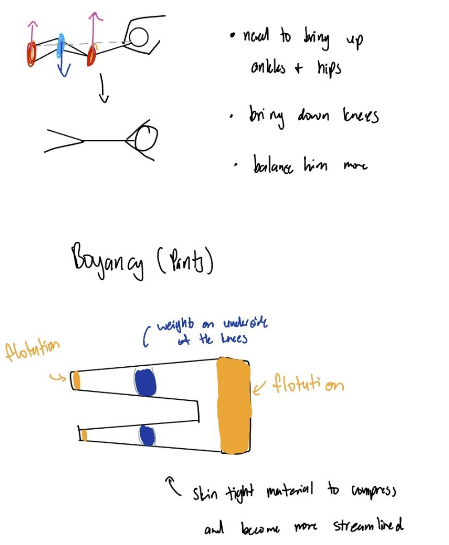

1.After creating some general preliminary sketches for an idea for our solution we came to a consensus on the general shape/idea of our design.

2. We created some general prototypes of our ideas to show during the TA meetings iterating until we reached our first 3D printed prototype (Identifiable with white rod component)

3. From TA meetings decided to adopt KISS method (keep it simple, stupid) rather than going for a complex solution

4. After experiencing issues with the materials on our initial prototypes we eventually printed out of PLA+ which was able to withstand basic forces,

5. We testing the device in water once before finding some issues related to jamming of the mechanism so we reprinted for the final prototype this time also making our solution neutrally buoyant so it is Ironman ready.

6. Overall printed over 2 KG worth of material and over 70 hours of print time to reach the final product for the GlideMaster.

- ❌Previous sketches/ideas were based on a lot more complex mechanisms and were very hard practically to execute.

- ✅We decided to keep the idea more simple and instead of trying to do multiple things at once just stick to straightening the knee joint and keeping the legs together to streamline the body

- ❌ Initial design for Velcro straps were thin and didn’t have the hooks. This caused it to be difficult to anchor the legs and also harder to wrap around for individuals with dexterity issues. It also was not waterproof

- ✅Redesigned using new Velcro which was waterproof and significantly wider with loops sewed at ends to solve the challenges faced above.

- ❌ Initially when we printed with PLA the device wasn’t strong enough and the device broke upon testing. This is why we decided to try PETG which was too brittle.

- ✅Decided to print final product with PLA+ which was a stronger and had a higher tensile strength therefore not snapping under load.

Design Considerations

Accessibility and comfort

- Thumb hooks and easy-to-use Velcro straps to accommodate users with limited hand mobility and dexterity.

- Soft-sided waterproof Velcro straps and beveled edges to reduce skin irritation and potential injuries.

Streamlined Shape and General design.

- Streamlining: Includes holes and aerodynamic shapes in the design to minimize hydrodynamic drag and enhance swimming performance.

- Neutrally buoyant: Adjusted the infill percentage to make the brace neutrally buoyant, preventing additional drag or difficulty for the user.

Compliance and Cost effectiveness

- Designed the brace to adhere to Ironman guidelines, avoiding flotation devices and limiting the number of anchoring points.

- Utilized 3D printing for a low-cost production process, with the possibility of further reducing costs through mass production and alternative manufacturing methods.

Final Design

Final Prototype

- The final solution, GlideMaster, is a cost-effective and user-friendly swimming brace specifically designed for quadriplegics like David.

- It enhances swimming performance by reducing hydrodynamic drag and ensuring a streamlined position in the water.

- Made from PLA+, the neutrally buoyant brace features a knee-locking mechanism, Velcro straps for a secure fit, and thumb hooks for accessibility.

- GlideMaster adheres to Ironman guidelines and promotes independence for individuals with physical challenges, providing an innovative solution for improved swimming experiences.

Personal Reflective Summary

Keep It Simple, Stupid

The GlideMaster project (DP-4) was very enjoyable as I had amazing group members that contributed well throughout the design process. Furthermore as the last design project of the year, expectations were up to create something that actually worked. Even while we accomplished this however, we encountered some challenges along the way which really are just opportunities for myself to grow.

One of the main challenges we faced was striking a balance between the complexity and simplicity of our prototype. As we were working with a real-life client with ambitious goals, we naturally wanted to create a solution that would fulfill all of David’s aspirations. This involved considering things such as an electronic mechanism to help him kick, using complicated gear and pully systems to straighten his legs and for a while we even considered making a full body swimming device. However, we realized that given the scope of the project, we had to acknowledge that it wasn’t a practical or feasible approach. Therefore as a team, we decided to adopt the KISS principle – Keep It Simple Stupid. This decision allowed us to refocus our efforts on more specific goals and ultimately develop a solution that truly worked for David.

Looking back on this project, maybe making a more complex solution would be more interesting and help me expand my learning but in order to provide a solution which meets our objectives we truly needed something more simple. Especially after doing a very complex DP-3 I believe DP-4 definitely did teach me the importance of KISS and keeping things simple sometimes being a better more practical solution that actually works.